VOL. 07 | ISSUE 3 | September 2024

‘Controlling Our Destiny’: New Mexico Operations Charts New Path for Managing Maintenance

The tiny room holds only a handful of people.

Beneath the din of an overworked air conditioner and impact drills just outside paper-thin walls, there is another sound – or rather, the absence of one. It is the silence that follows a collective sigh of relief and the sudden realization of what is to come.

When they first started on this journey, the Chino mill planners knew they would at the very least help improve an untenable situation, making the abundance of incomplete and obsolete maintenance plans more manageable for those who followed.

But now that they have taken their first real step, reviewing, revising and reducing the first of 1,400 plans, this team of “scrubbers” also finds it is on a quest to update now-obsolete practices, preserve institutional knowledge and change the face of maintenance across New Mexico Operations.

Navigating change

It all started at the end.

In 2020, the Chino mill shut down because of the pandemic. While necessary at the time, it was an action that planted the seeds for a bigger problem by the time it restarted.

“People came back to a different world in 2021,” said Kevin Perry, Senior Planner-Chino. “Many of the furloughed never returned, the mill was operating under single-line conditions, and new planners had to determine which maintenance plans in the deactivated slate were the right ones to implement.”

Either the equipment determines the work, or the equipment determines the downtime. There’s so much going on here that could give us a long future – it’s time we started controlling our own destiny.

According to Perry, it was the perfect storm.

Chino had lost a considerable amount of its institutional knowledge at a time when it needed it most. With several benchmarks for planned maintenance compliance being set as goals across North America operations, Don Jensen, Concentrator Manager-Chino, requested a maintenance assessment from the company’s Operational Improvement team so he could be proactive in meeting those goals, increase asset efficiency and increase production.

In one of the weekly meetings, Will Garard (center) takes notes as his planners discuss their progress.

“This was the start of a continued philosophical approach of what we needed to do,” Jensen said. “What the assessment gave John and me were opportunities throughout the division to bring that philosophy to the forefront.”

John Swagzdis, Shared Services Manager-New Mexico Operations, and Will Garard, Reliability Superintendent-New Mexico Operations, were determined not to miss those opportunities.

As the first part of a two-pronged approach, the pair tasked their team with culling the plans to minimize redundancy and distill what remained into comprehensive, step-by-step instructions for maintaining the mill. The second prong involved reexamining the new maintenance plans at regular intervals and, especially after unplanned downtime, ensuring a cycle of continuous improvement.

Aaron Cortado, Operational Excellence Facilitator, looks at the system backend, where he provides continuous improvement as the team refines its system.

For his part, Perry took a one-bite-at-a-time approach to eating the elephant. Looking at the biggest hitters for downtime, Perry and his team of planners – Joe Murillo, Raul Madrid, Cruz Ruelaz and Edward Leyba – set a goal of scrubbing the Vertimill, regrind and recycle areas by the end of the second quarter. They then worked with site subject matter experts and supervisors to make sure they were enshrining only the most accurate, in-depth instructions.

The team also had an ace up its sleeve.

Tracking critical information

One of the Operational Excellence facilitators at Chino, Aaron Cortado, worked with the team to build a system that not only allowed it a bird’s-eye view of the problem but also separated the wheat from the chaff, tracked the approval process of scrubbed plans and attached relevant documentation like manufacturer’s guidelines.

By July, the team had used this new system to reach its goal. Of the more than 300 plans in the target areas, they were able to delete 75 percent and revise over 70 items for continued use – but that feat was more important than just numbers.

“The real success was being able to refine our process,” Perry said.

Perry admits there were some stumbles, and there remain additional hurdles, including everything from changes in equipment to suitable employee buy-in. Still, Perry sees those first steps as an indicator of how the team will eventually make greater strides and expand the system’s use.

Details Matter

The scrubbing team found little consistency in how past maintenance plans had been created or approved.

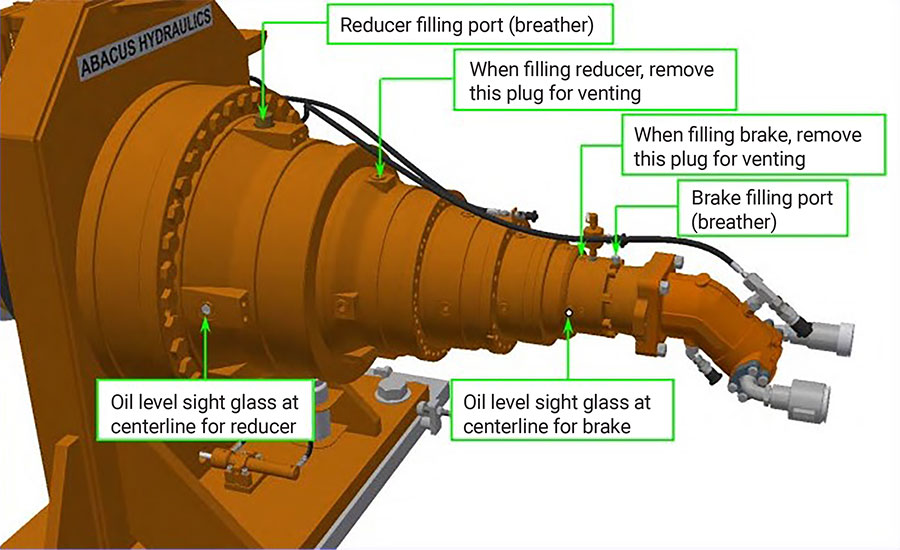

“They were all over the map,” said Kevin Perry, Senior Planner-Chino. “You might have a PM (planned maintenance) that just says, ‘check oil’ but never tells you what you’re looking for.”

A harder problem involved plans that contained useful information spread out across multiple plans. As the team pieced together that puzzle, they honed in on the ideal maintenance plan and how to capitalize on Chino’s strong tablet adoption.

In particular, the team focused on creating detailed maintenance plans that frequently referenced manuals and manufacturer’s guidelines – source materials that were linked and accessible on the tablet straight from those digital plans.

As the team forges on, they not only look to expand coverage to the remaining areas of the mill but also to other areas across New Mexico Operations. It is also important that the system evolves to allow users more input, creating the sort of feedback loop that enables continuous improvement for more than just systems and equipment. By making the system an integral part of the workflow and getting more eyes on it, the team sees an opportunity to demonstrate a better way forward and lay the groundwork for embracing a new maintenance philosophy.

“Either the equipment determines the work, or the equipment determines the downtime,” said Swagzdis. “There’s so much going on here that could give us a long future – it’s time we started controlling our own destiny.”